In the world of manufacturing, selecting the right materials is crucial to ensuring product quality and long-lasting performance. Among the many types of steel available, cold rolled steel is often the top choice for manufacturers across various industries. Known for its superior strength, smooth finish, and versatility, cold rolled steel has earned its place in the production of high-quality products. As a trusted supplier, Dass Steel Service Centre offers top-notch cold rolled steel for diverse manufacturing needs.

What Is Cold Rolled Steel?

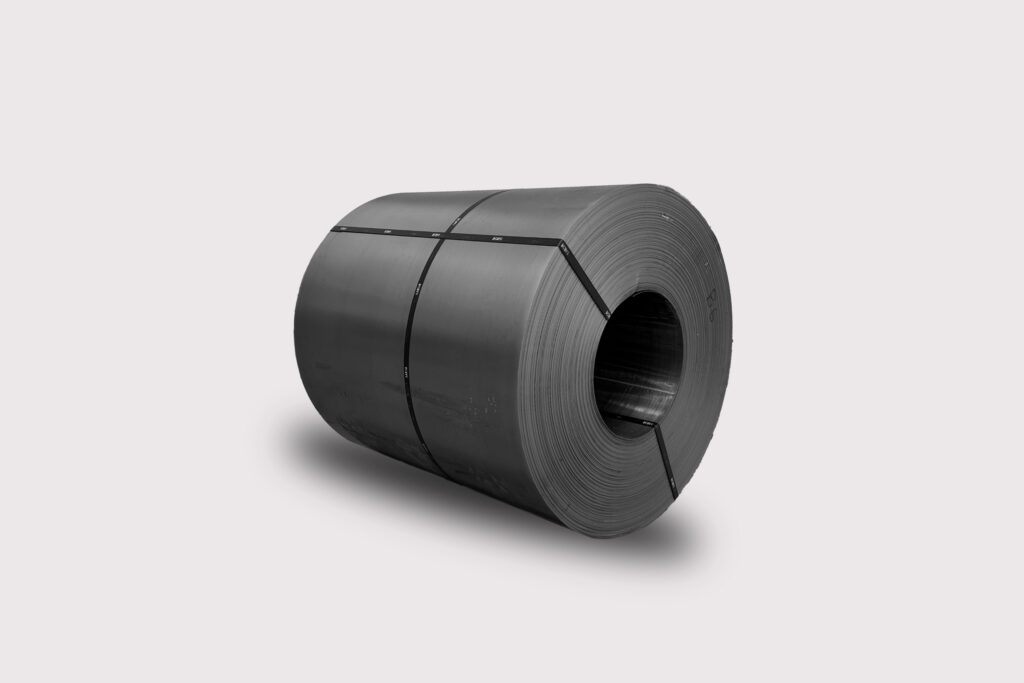

Cold rolled steel is a type of steel that has been processed at room temperature, which makes it stronger and more durable than its hot rolled counterpart. During the cold rolling process, steel coils are passed through rollers at room temperature, giving them a smooth finish and improving the metal’s grain structure. This results in a material that is harder, more precise, and more suitable for various applications, especially those that require fine detailing.

Advantages of Cold Rolled Steel for Manufacturing

1. Superior Surface Finish

One of the most prominent benefits of cold rolled steel is its smooth and refined surface. At Dass Steel Service Centre, we provide cold rolled steel coils with consistent, clean surfaces, making it ideal for industries that require high-quality finishes, such as automotive, appliance manufacturing, and steel fabrication.

2. Enhanced Strength and Durability

The cold rolling process increases the material’s tensile strength, making cold rolled steel more durable than other types of steel. This increased strength allows manufacturers to produce products that can withstand harsh conditions, making it perfect for use in heavy-duty applications, such as structural steel and components for machinery.

3. Precision and Consistency

For industries where precision is paramount, cold rolled steel is the ideal material. The cold rolling process allows for exact control over thickness, ensuring that each coil maintains uniformity across the entire production batch. At Dass Steel Service Centre, we pride ourselves on offering cold rolled steel products with tight tolerances, ideal for precision engineering and metalworking.

4. Versatility in Applications

From the automotive sector to construction and manufacturing, cold rolled steel is used across many industries. It’s frequently used in producing steel products such as automotive body panels, structural supports, and precision components. Our cold rolled steel is versatile enough to meet the unique needs of different sectors, providing manufacturers with the right material for their projects.

5. Improved Formability

Despite its enhanced strength, cold rolled steel maintains good formability. This makes it easier to shape and manipulate during steel fabrication without compromising the material’s structural integrity. Manufacturers can bend, cut, and form cold rolled steel into intricate shapes and sizes, whether for structural beams or components in machinery.

Dass Steel: Your Trusted Cold Rolled Steel Supplier

At Dass Steel Service Centre, we specialize in providing cold rolled steel coils that meet the highest standards for strength, durability, and precision. Whether you’re in the automotive industry, construction, or another sector requiring top-quality steel products, we ensure that our materials deliver outstanding performance and long-lasting results.

Our expert team is always available to help manufacturers select the right material for their specific needs. We understand the demands of the manufacturing process and are committed to providing superior steel coils and other steel products that contribute to the success of your business.

Conclusion

Cold rolled steel is the ideal choice for manufacturers who require high-strength, precise, and durable materials. With its smooth finish, improved formability, and versatility, it is the preferred option for many industries, including automotive, construction, and steel fabrication. As a leading steel supplier, Dass Steel Service Centre offers premium cold rolled steel to meet the evolving demands of today’s manufacturers. Let us help you enhance your manufacturing process with the best materials available.